目录

Advantages of Silicone Tableware

Silicone tableware is renowned for its heat stability, flexibility, and durability. It can withstand temperatures up to 400°F, making it ideal for high-heat cooking and freezing leftovers. The material’s flexibility ensures its resilience against damage from drops and impacts, while its degradation into large pieces reduces the risk of environmental harm. Additionally, silicone tableware is a healthier alternative to traditional non-stick cookware, as it does not contain perfluorinated chemicals (PFAS) that can be harmful to the environment and human health.

Target Market Analysis

According to QY Research, the global market for silicone tableware is experiencing significant growth, with a projected CAGR of 13.6% from 2024 to 2030, reaching a market size of $20.1 billion. The Asia-Pacific region, excluding China, is expected to grow at the fastest pace, indicating substantial potential for our silicone factory to tap into emerging markets. Our focus on wholesale ensures that we cater to retailers, distributors, brand owners, and supermarkets who seek high-quality silicone tableware in bulk.

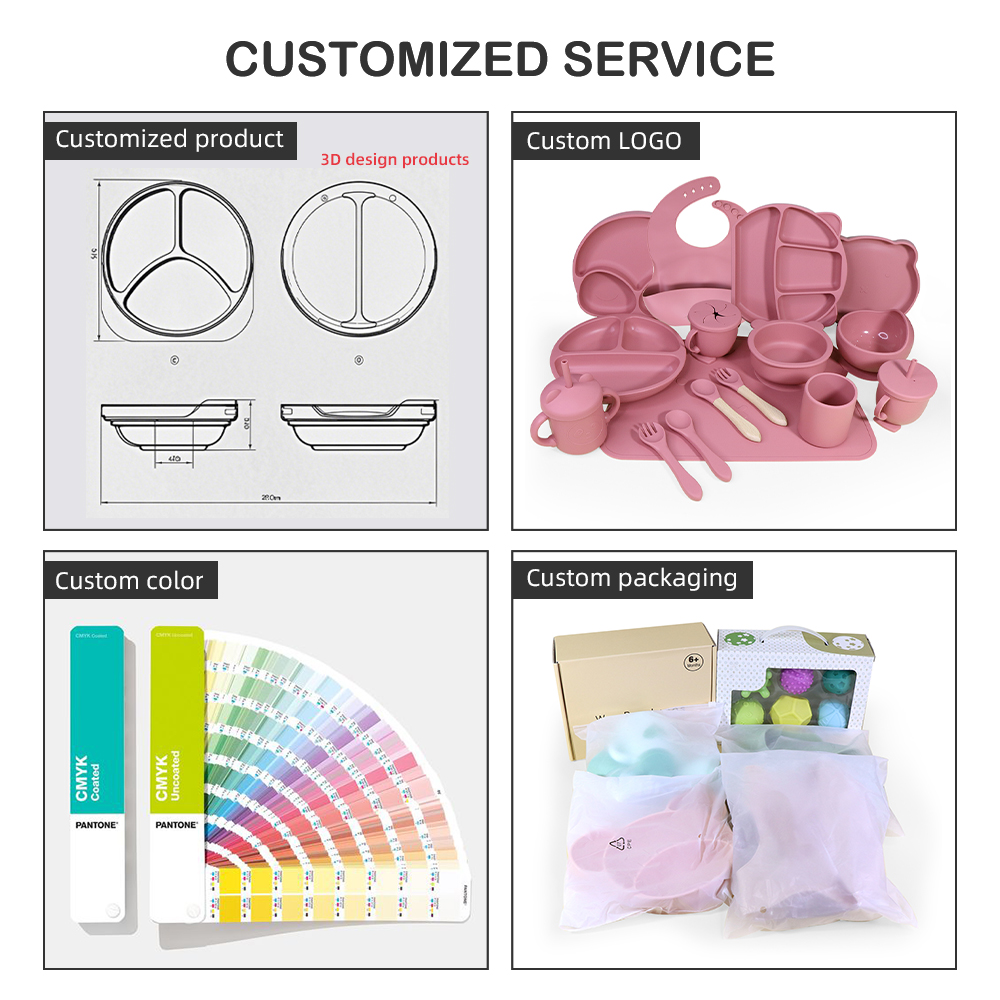

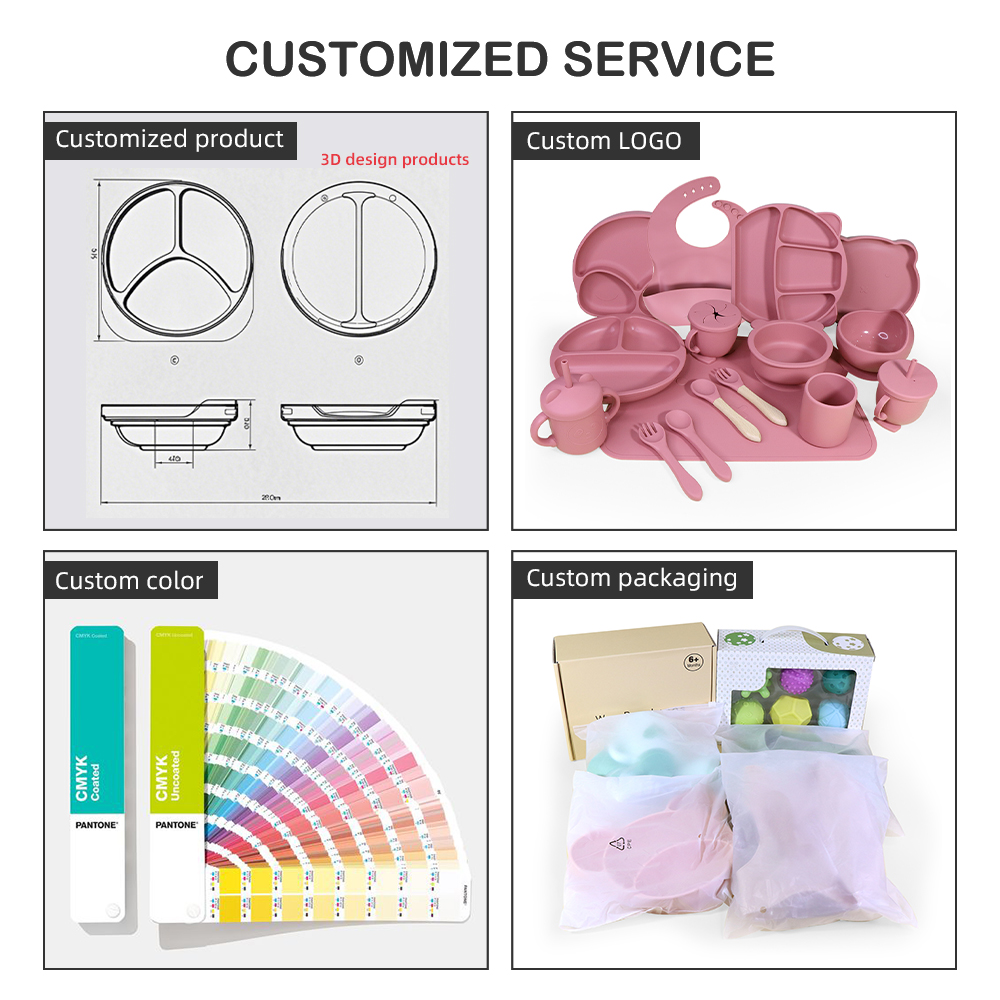

Product Series and Customization Services

As a leading silicone factory, we offer a diverse product series that includes various silicone tableware items such as plates, bowls, cups, and cutlery. Our customization services allow clients to specify their desired colors, shapes, sizes, and packaging, ensuring that each order meets their unique branding and functional requirements. With low MOQs and free design drafts, we support OEM and ODM services, making us a flexible partner for wholesale clients.

Consumer Benefits and Comparison with Traditional Tableware

From a consumer perspective, silicone tableware offers several advantages over traditional tableware. It is lightweight, easy to clean, and odor-resistant, making it a popular choice for both indoor and outdoor use. Its non-slip properties and bright colors add to its appeal for families with children. Compared to traditional materials, silicone is more durable and less likely to break, providing long-term value. Additionally, silicone’s non-porous surface makes it easier to maintain hygiene and resist bacterial growth.

Supply Chain and Logistics Advantages

Our silicone factory boasts a robust supply chain with full production lines, from mold setting to shipping, ensuring a streamlined process from order to delivery. We have our testing lab to guarantee product quality, and we have passed various international certifications, including ISO 9001 and CE. Our logistics advantages include efficient lead times, with samples available in 3 working days and mass goods in 25 days, making us a competitive choice for wholesale clients who require timely deliveries.

Industry Standards and Certifications

Adherence to industry standards is crucial in the silicone tableware industry. Our products comply with international safety and quality requirements, such as FDA CFR 21 parts 175-189 and REACH regulations in Europe. We ensure that our silicone tableware meets all necessary food contact standards, providing our clients with peace of mind and helping them avoid potential recalls and maintain trust in their products.

Industry Dynamics and Future Outlook

The silicone tableware industry is constantly evolving, emphasizing innovation and sustainability. As a 硅胶厂, we are committed to staying at the forefront of these trends, offering products that not only meet current demands but also adapt to future market shifts. People’s awareness regarding environmental issues is escalating, and the growing demand for sustainable products is positioning silicone tableware as an eco-friendly substitute for traditional materials. It is anticipated that the long-term market demand for our offerings will persist in expanding.

In conclusion, silicone tableware’s versatility, durability, and safety make it an ideal product for the wholesale market. As a silicone factory, we are dedicated to providing our clients with the highest quality products, tailored to their specific needs, and backed by our commitment to industry standards and continuous innovation.