目录

在当今追求健康生活方式的潮流中、 硅胶水瓶 硅胶水瓶以其轻便、耐用、防摔等特点受到许多消费者的青睐。然而,笔者对包括亚马逊在内的几家主流电商平台进行了调研,发现硅胶水瓶的异味已经成为许多用户反馈中经常提到的痛点。本文旨在探讨消费者如何有效去除硅胶水瓶的异味,同时揭示硅胶水瓶在生产过程中去除异味的关键工艺,为消费者带来更好的使用体验。

硅胶水瓶除味消费者指南

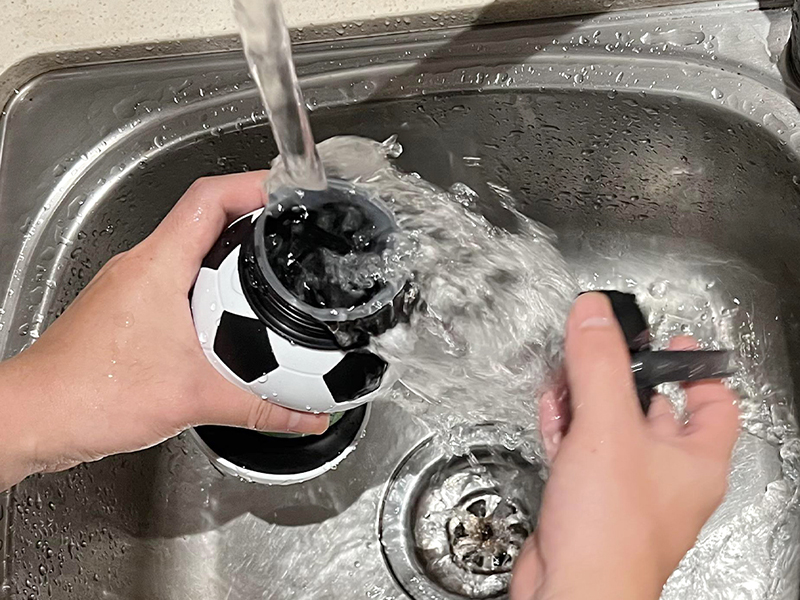

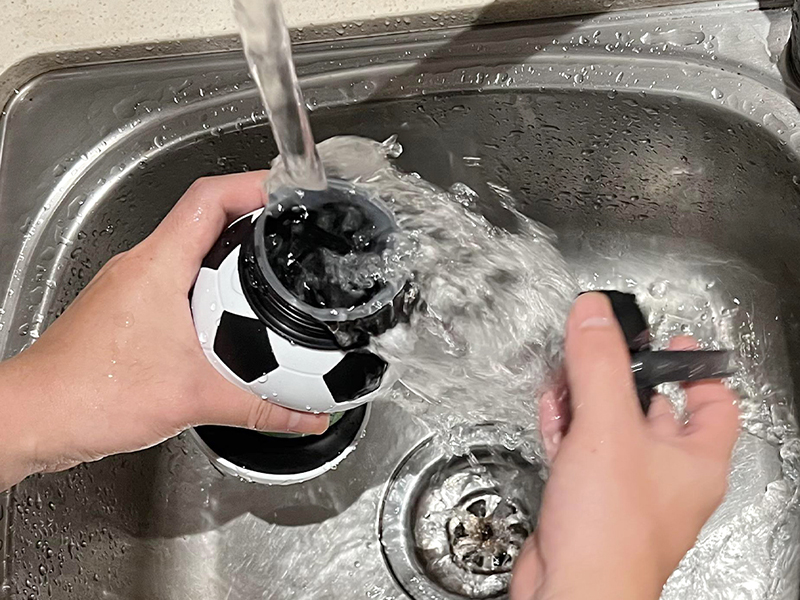

1. 用温水清洗

首次使用前,用温水加少量中性洗涤剂彻底清洗硅胶水瓶内外,然后用流动水冲洗,这一步有助于去除附着在表面的杂质和最初的气味。

2. 沸水浸泡法

将开水倒入水瓶,盖紧盖子,静置几小时或一夜,高温有助于加速气味分子的释放。第二天倒掉水,再次冲洗干净,自然晾干。

3. 自然疗法:柠檬汁/醋

在水中滴几滴柠檬汁或白醋,然后将瓶子浸泡在溶液中几个小时--天然酸性可以中和异味--之后彻底冲洗干净。

4. 小苏打创造奇迹

小苏打和水混合成糊状,均匀涂抹在水瓶内壁,静置一段时间后冲洗,小苏打的去污除臭能力不容小觑。

生产过程中的气味管理

1. 原材料的选择

源头控制是关键。高品质、低 VOC(挥发性有机化合物)的食品级有机硅原料可以从根本上减少产生气味的可能性。

2. 优化脱模剂

脱模剂是气味的主要来源。采用无味、环保的食品级脱模剂,并在生产后进行彻底清洗,可确保将脱模剂残留降至最低。

3. 硅胶水瓶的二次硫化

硅胶水瓶成型后,需要经过二次硫化过程,即在高温下进一步固化,这不仅能增强产品的物理特性,还有助于完全挥发残留的气味分子。

4. 硅胶水壶的高效通风和储存

生产完成后,产品放置在通风良好的环境中,自然散发残留气味,避免在封闭空间内长时间堆放,减少气味积累。

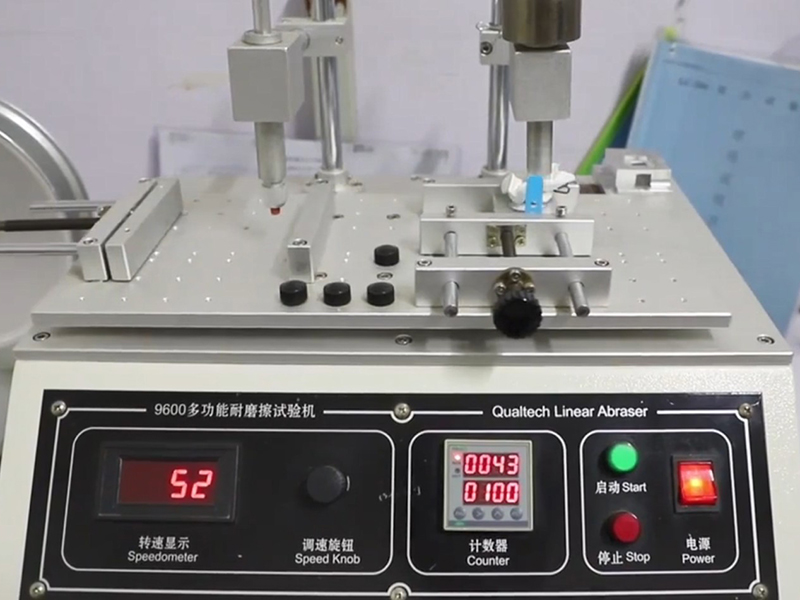

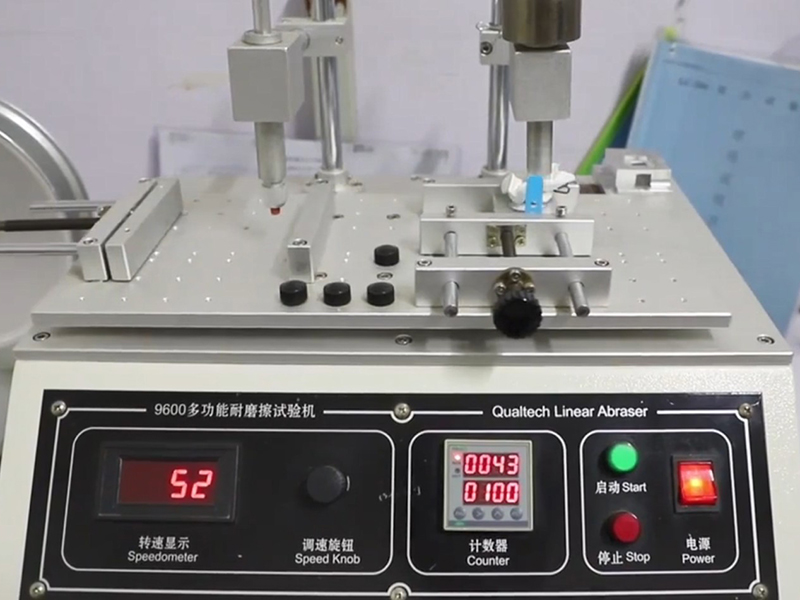

5. 严格的质量检查

设立专门的嗅觉检测环节,确保每一个硅胶水瓶在出厂前都经过严格的风味评估,不合格产品不得流入市场。

综述

消费者可以通过简单的家庭处理有效减少硅胶折叠水壶的异味问题,而生产企业则需要从源材料选择到生产工艺的每一个细节入手,综合运用多种策略从根本上解决异味问题,共同打造清爽、健康的饮水体验。未来,随着材料科技的进步和生产工艺的优化,硅胶水瓶的异味问题有望得到根本改善,为消费者带来更满意的体验。