内容

Silicone, a versatile and resilient material, has been gaining significant traction across various industries. Its unique properties, such as durability, flexibility, and resistance to extreme temperatures, make it an ideal choice for a wide range of applications. As we look towards 2025, the silicone industry is poised for substantial growth, driven by technological advancements and evolving consumer preferences. This article delves into the key trends shaping the silicone products market and highlights the most promising silicone trend products.

Rising Demand for Eco-Friendly Silicone Products

Environmental sustainability is a paramount concern in today’s world, and the silicone industry is no exception. Consumers are increasingly seeking eco-friendly alternatives, and silicone products are answering this call. One of the significant trends is the development of biodegradable silicone materials. These innovative products are designed to break down naturally over time, reducing the environmental impact of waste. For instance, biodegradable silicone bags and containers are becoming popular for food storage, offering a sustainable solution that aligns with the growing emphasis on reducing plastic waste.

Versatile Applications in Healthcare and Medical Devices

The healthcare sector continues to be a significant driver of silicone product innovation. Silicone’s biocompatibility and hypoallergenic properties make it an ideal material for medical devices. In 2025, we expect to see an expansion in the use of silicone for advanced medical applications. For example, silicone-based implants and prosthetics are being developed with enhanced durability and improved patient comfort. Additionally, silicone is being utilized in the creation of smart medical devices, such as wearable sensors and diagnostic tools, which can monitor vital signs and provide real-time health data.

Innovative Designs for Consumer Electronics

The consumer electronics industry is another sector where silicone trend products are making waves. With the rapid pace of technological advancements, there is a constant need for materials that can withstand the demands of modern electronics. Silicone’s excellent thermal conductivity and electrical insulation properties make it a perfect fit for this industry. In 2025, we anticipate the introduction of silicone-based cooling solutions for high-performance devices, such as smartphones and laptops. These innovations will help maintain optimal operating temperatures, enhancing device performance and longevity.

Enhanced Durability and Performance in Automotive Applications

The automotive industry is also witnessing a surge in the use of silicone products. As vehicles become more technologically advanced, the need for durable and reliable materials is paramount. Silicone’s ability to withstand extreme temperatures and its resistance to chemicals make it an ideal choice for automotive components. In 2025, silicone trend products in the automotive sector will include high-performance gaskets, seals, and hoses that can endure harsh operating conditions. Furthermore, silicone-based coatings and adhesives will be used to improve the durability and performance of various automotive parts.

Customization and Personalization in Silicone Products

Personalization is becoming a key factor in consumer purchasing decisions, and silicone products are no exception. Manufacturers are increasingly offering customizable options to cater to individual preferences. For example, silicone phone cases and accessories can now be personalized with unique designs, colors, and patterns. This trend is not limited to aesthetics; it also extends to functionality. Consumers can choose silicone products with specific features tailored to their needs, such as anti-slip properties or enhanced durability.

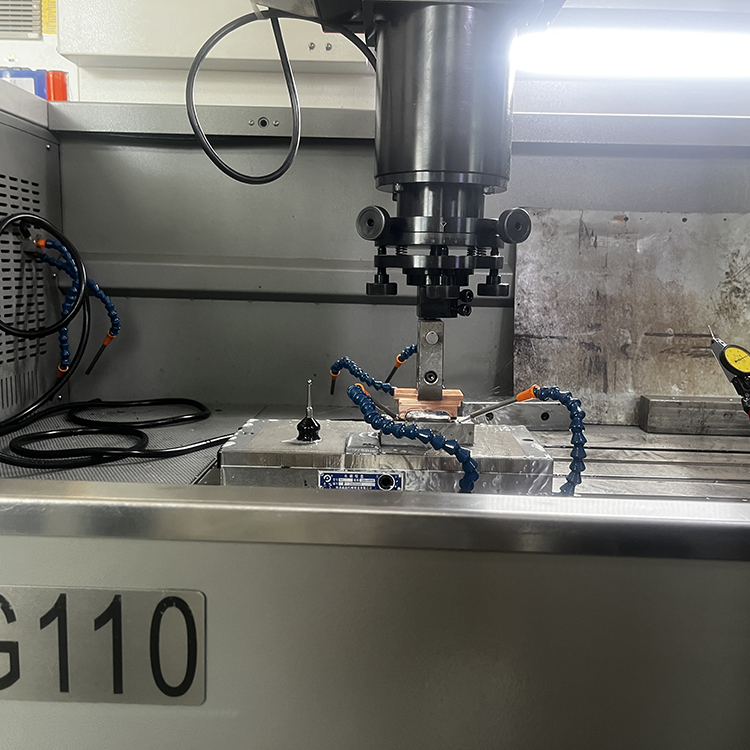

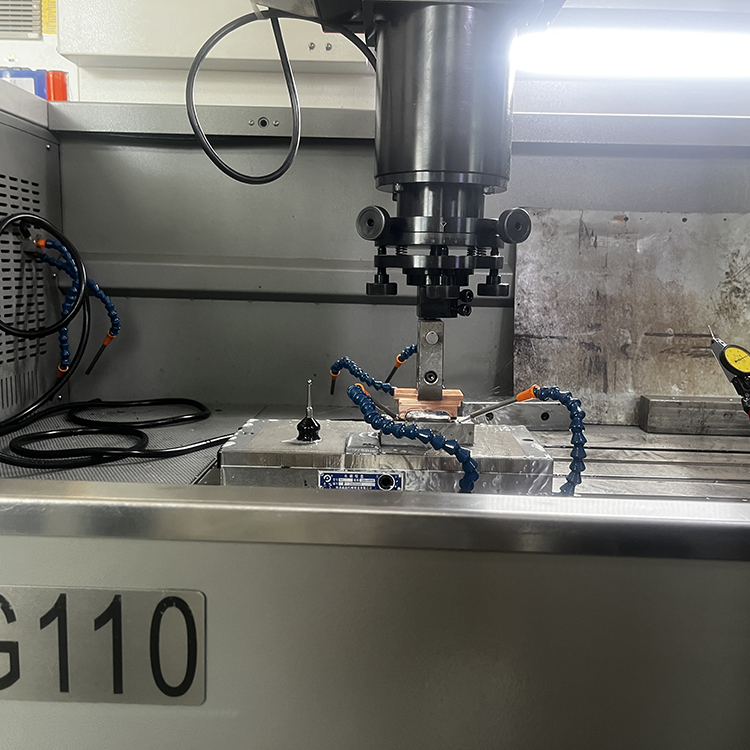

The Rise of Liquid Silicone Rubber (LSR) Products

Liquid Silicone Rubber (LSR) is emerging as a significant trend in the silicone products market, offering numerous advantages and applications. LSR’s unique properties, such as its excellent thermal stability, chemical resistance, and biocompatibility, make it an ideal material for a variety of industries. The ability to achieve high precision and complex geometries through injection molding processes further enhances its appeal.

Applications and Advantages of LSR

– Consumer Electronics:

LSR’s use in electronics is expanding due to its excellent electrical insulation properties and resistance to high temperatures. It is commonly used for the production of seals and gaskets in electronic devices, ensuring that they remain waterproof and dustproof. This is particularly important for devices like smartphones and tablets, where durability and reliability are paramount.

– Automotive Industry

The automotive sector is another major consumer of LSR. It is used for the production of various components, including fuel system parts, sensors, and electrical connectors. LSR’s ability to withstand extreme temperatures and its resistance to chemicals make it an ideal material for these applications, ensuring the longevity and performance of automotive systems.

– Silicone Household Products

The manufacturing process of LSR allows for high levels of customization. Water bottles and cups can be designed in various shapes, sizes, and colors, catering to different consumer preferences and needs. This versatility also extends to functional features, such as built-in filters, straws, or compartments for carrying small items.

結論

The silicone products market is experiencing a dynamic transformation, driven by technological innovations and shifting consumer demands. As we move into 2025, the industry will continue to evolve, offering a diverse range of silicone trend products that cater to various sectors. From eco-friendly solutions to advanced medical applications and personalized consumer goods, silicone is proving to be a material of the future. By staying informed about these trends, businesses can capitalize on new opportunities and meet the evolving needs of their customers.