Contents

Silicone bottles are popular for their durability, flexibility, and eco-friendliness. But what goes into the making of these versatile containers? This article delves into the manufacturing process of silicone bottles, focusing on compliance with FDA and LFGB international safety standards.

Design Phase: Shaping the Silicone Bottle

The journey of a silicone bottle begins with product design. Our silicone factory starts by understanding the customer requirements and functional needs of the water bottle, including its shape, size, and purpose. We use advanced software like CAD or PRO/E to create detailed designs that meet these specifications.

Mold Making: The Foundation of Silicone Bottles

Following the design phase, we proceed to mold making. Based on the finalized drawings, our mold designers program the CNC machines to carve the initial rough shape. We then use electric discharge machines (EDM) and precision engraving machines for fine processing. The final step involves surface treatment of the molds, which may include polishing, electroplating, and etching to ensure the mold surface is perfect for producing high-quality silicone bottles.

Material Selection and Compliance

We utilize High Consistency Rubber (HCR), also known as high稠度橡胶, for the production of our silicone bottles. HCR is a silicone material with excellent mechanical and physical properties, making it ideal for manufacturing high-quality silicone bottles. Unlike Fumed Silica and Precipitated Silica, which are used as fillers to improve the physical properties of silicone rubber, HCR is a high molecular weight polymer with silica fillers that provide the material with its distinct characteristics.

Mixing and Coloring: The Art of Consistency

The next step in the silicone bottle manufacturing process is mixing and coloring. We prepare the HCR material by combining it with specific additives to achieve our custom silicone bottles’ desired color and properties. This mixing process is crucial for achieving a uniform mixture, which is essential for consistent curing and final product quality.

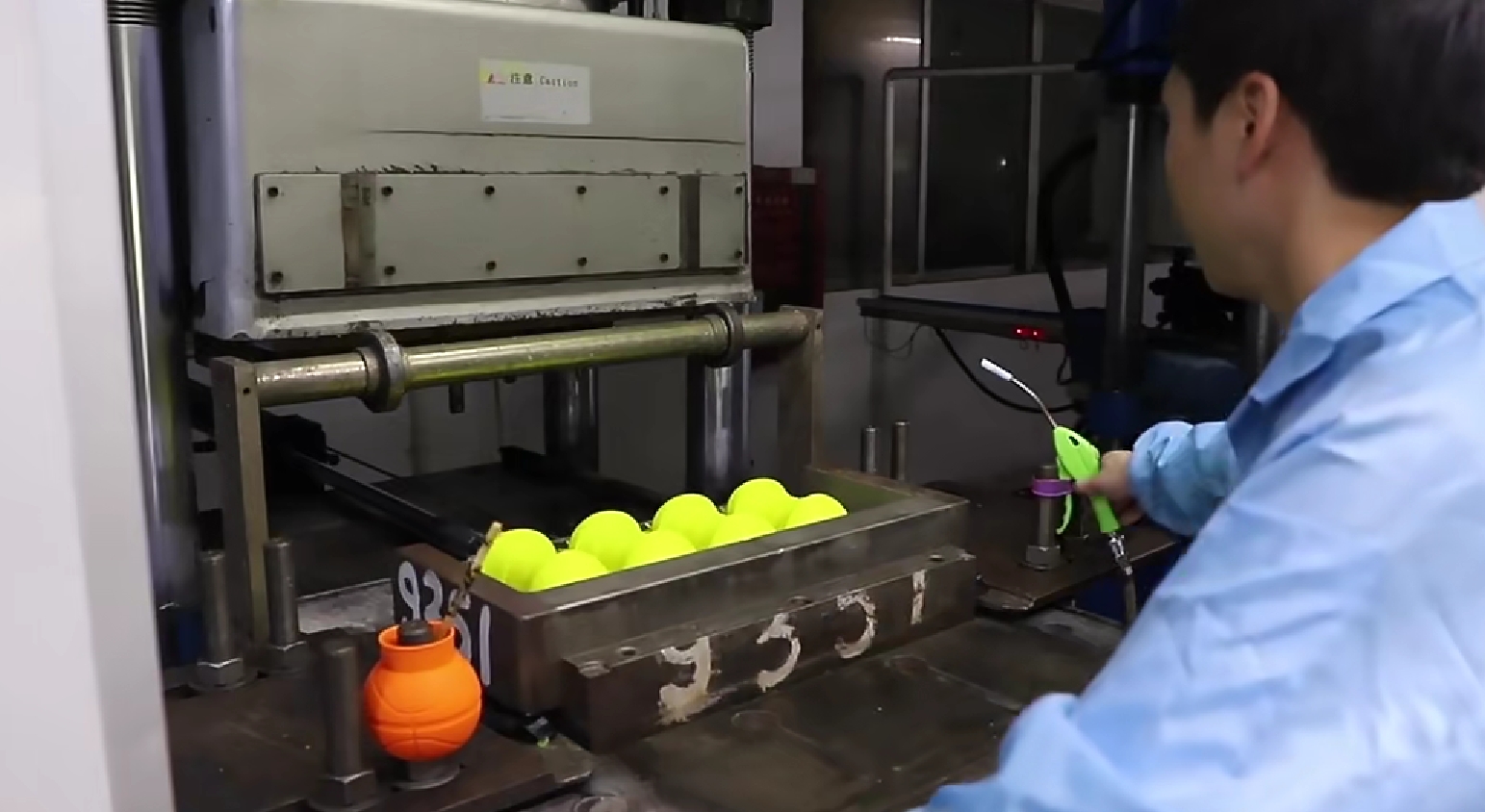

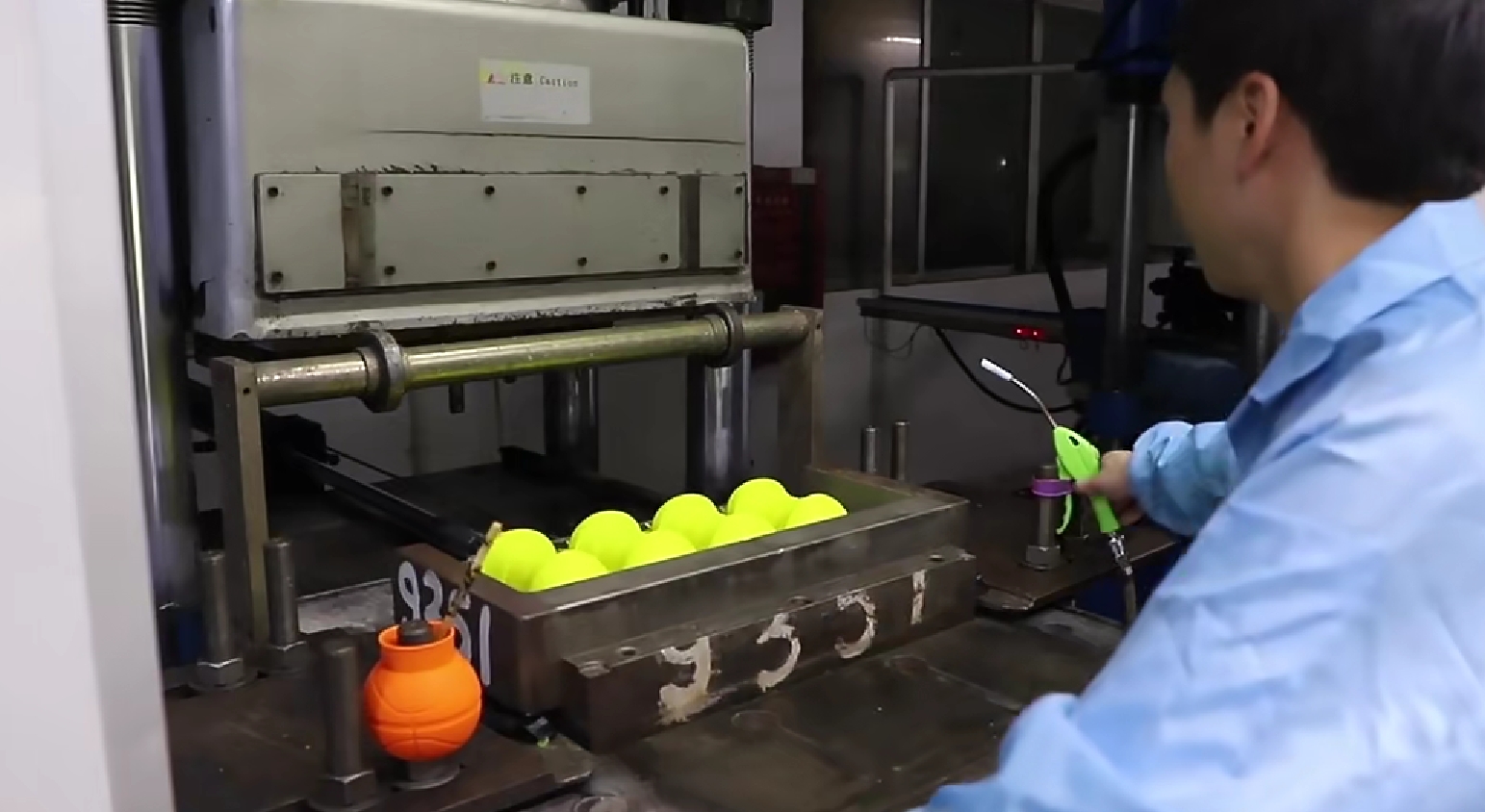

Molding and Curing: Shaping and Strengthening

After the mixing and coloring process, the HCR mixture is ready for molding. The HCR is poured into precision molds and subjected to heat and pressure to take the shape of the mold. This process is critical in determining the physical properties of the silicone bottle, such as its elasticity, tensile strength, and resistance to high and low temperatures.

Curing Process: Ensuring Structural Integrity and Quality

The curing process is where the HCR takes on its final properties. For FDA compliance, peroxide curing is sufficient and more cost-effective, while platinum curing is the preferred choice for high-purity applications and is suitable for the manufacturing of products that need to comply with LFGB standards. Platinum-cured silicone is recognized for its superior purity and is often used in products that come into direct and long-term contact with food, ensuring they pass the rigorous tests required by both standards.

Post-Curing: Eliminating Residuals for Safety

Post-curing, also known as secondary vulcanization, is essential for eliminating all potential residues and ensuring the silicone bottle is safe for use. To meet LFGB compliance, common post-curing conditions involve heating at 200°C (392°F) for 4 hours. This process ensures that the silicone product is free from any substances that may migrate into food, making it safe for use in the European market. For FDA compliance, post-curing can be effective at lower temperatures or shorter durations, with heating at 150°C (302°F) for 2-4 hours being sufficient.

Quality Control and Inspection

Quality is paramount in silicone bottle manufacturing. Our silicone factory employs a rigorous quality control system that includes multiple inspection points. Each batch of custom silicone bottles is thoroughly checked for any defects in shape, color, and material integrity. We ensure that only the highest quality products reach our wholesale customers.

Custom Silicone Bottles: Meeting Wholesale Needs.

As a silicone factory, we specialize in custom silicone bottle production for wholesale clients. Our expertise in customization allows us to meet the unique requirements of each client, ensuring their products stand out in the market. Whether it’s for outdoor enthusiasts, fitness enthusiasts, or for everyday use, we can craft a custom silicone bottle to meet any requirement.

Packaging and Shipping for Wholesale

Once the silicone bottles have passed our stringent quality checks, they are carefully packaged to ensure they arrive in perfect condition. Our silicone factory specializes in bulk packaging, tailored for wholesale distribution. We understand the logistics involved in wholesale operations and ensure that our packaging and shipping processes are efficient and cost-effective.

![]()

![]()

Conclusion: The Expertise Behind Silicone Bottle Manufacturing

Silicone bottle manufacturing is a complex process that requires precision, expertise, and a commitment to quality. As a silicone factory, we pride ourselves on our ability to produce custom silicone bottles that meet the exacting standards of our wholesale clients. Our focus on customization, quality control, and efficient production makes us the go-to partner for businesses looking to offer silicone bottles in the market. Choose us for your custom silicone bottle needs, and experience the difference that expertise and dedication can make.